In recent years, the aluminum industry has made great progress in the production of aluminum materials, research and development of new alloys and performance improvement, and the production of large-section extruded materials, bringing the application of aluminum materials in bridge structures to a new level. The advantages of aluminum in the construction of pontoon bridges and movable bridges are self-evident, and it has also shown its talents in the construction of road bridges recently.

The application of the aluminum industry in urban flyovers has developed from practicality to both aesthetics and practicality. Aluminum alloy pedestrian bridges have gradually replaced cement and steel manufacturing due to their prefabricated assembly, quick installation, low maintenance cost, and non-corrosion characteristics footbridge.

The application of aluminum alloy materials in bridge engineering has a long history, dating back to the aluminum bridge deck on the Smithfield Street Bridge in Pittsburgh, USA in 1933. In the next 50 years, nearly a hundred aluminum alloy bridges were built around the world. Lighter in weight, more corrosion-resistant, 3 times longer in service life, and maintenance-free, this has become the main reason why foreign countries are keen on building aluminum alloy sky bridges.

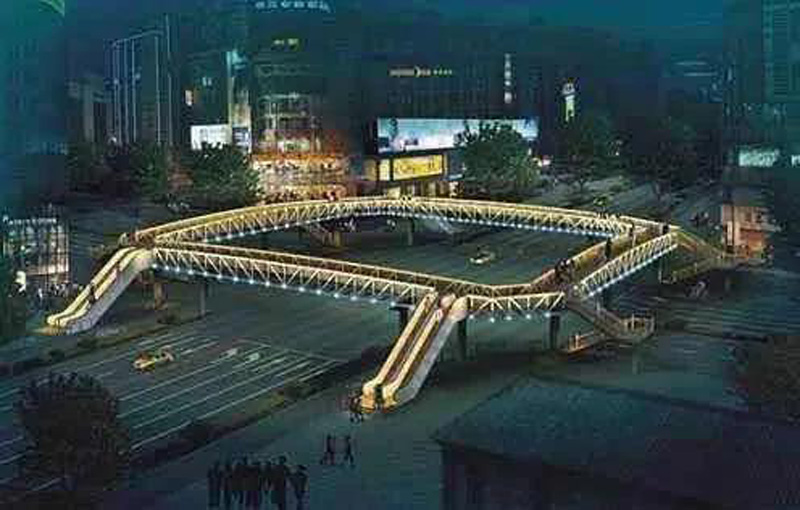

In 2017, the reconstruction of the two overpasses in the north and south of Dongdan on Chang'an Street in Beijing into an aluminum alloy truss structure was a sensation. Aluminum alloy flyover is a new potential field of aluminum application, and it is also a concrete practice of the transformation and upgrading of my country's aluminum industry. In 2019, in Zhaoqing, Guangdong, a 40-meter-long aluminum alloy pedestrian bridge officially debuted. This is also the first aluminum alloy pedestrian bridge with the longest span in Guangdong Province.

01. Durable

The deck of the first aluminum alloy pedestrian bridge in our province adopts the wear-resistant and weather-resistant aluminum alloy bridge deck independently developed by Aluminum Bridge, which is durable. The structural parts and railings are made of aluminum alloy with strong moisture-proof and corrosion resistance. The surface treatment process is mature, and it will not change color after many years of use.

02. Low maintenance cost

Aluminum alloy flyovers have strong corrosion resistance in wet or acid and alkali environments. As a result of high corrosion resistance, the maintenance cost during the entire life cycle is much lower than that of steel bridges. Nowadays, coastal cities such as Guangdong and Hainan are actively building aluminum alloy bridges. Climate impact is a factor that local governments must consider. Aluminum alloys just solve the major problem of bridge structure corrosion.

03. Fast installation

The aluminum alloy pedestrian bridge adopts prefabricated assembly technology, which can be directly installed on site and quickly, and can effectively reduce and avoid the impact on the normal life of surrounding social traffic and residents' travel during the construction process.

04. The shape is flexible and ever-changing

The surface treatment and extrusion process of aluminum alloy are very mature, which can produce bright and aesthetic appearance, flexible and changeable color, strong plasticity, and can be combined with different scenes and themes to customize the unique shape and appearance, such as truss bridge and arch bridge , modeling bridges, etc., more fashionable and atmospheric.

05. Environmental protection, recyclable

As a bridge material, aluminum has a series of superior properties that are difficult to replace, and is considered to be the most dynamic and vital new material. After the life cycle of aluminum alloy bridges expires, almost all waste aluminum can be recycled, which is a typical green and environmental protection building material.

06. "Lightweight" goes into battle, with light weight and high strength

The "lightweight" feature of the aluminum alloy pedestrian bridge greatly reduces the requirements for the foundation of the bridge construction. Why can the aluminum alloy pedestrian bridge be constructed in the workshop and "place" easily on the road? The secret lies in the "weight" of the aluminum alloy. The aluminum bridge deck is much lighter than concrete, only two-thirds of the original bridge's self-weight, which can save time, improve efficiency and reduce costs to the greatest extent during the construction process.

In the future, aluminum alloy bridges will have broad development prospects in China.

1. China's current high-speed rail construction is in full swing. In addition, the terrain in the central and western regions is relatively complex, with many canyons and rivers, and a large number of bridges need to be built in the process of erecting the railway. The aluminum alloy bridge will have a relatively broad potential market due to its advantages such as convenient transportation and light weight.

2. The common problems of steel are easy to rust and poor low temperature performance. Rusted steel will seriously affect the firmness of the bridge, which not only brings greater maintenance costs, but also poses serious safety hazards. Poor low temperature performance will make the steel bridge unable to work normally under some harsh weather conditions. Aluminum alloy materials generally have relatively strong corrosion resistance and low-temperature performance, so they can be widely used in various climatic conditions and are durable. Although the cost of aluminum alloy bridges is generally high, the low maintenance costs in the later period may reduce the price gap to a certain extent.

3. The research on aluminum bridge decks at home and abroad has been very mature, and the application is also very extensive. The ever-increasing level of material research and development also provides a technical guarantee for the development of new alloys that meet different performance requirements. In recent years, domestic aluminum manufacturers have gradually set their sights on the field of industrial aluminum profiles.

4. The subway construction in major cities in China has very strict requirements on the pressure from the ground. Due to the huge advantages in quality of aluminum alloy bridges, it is foreseeable that more aluminum alloy pedestrian bridges and road bridges will be designed and used in the future.

Aluminum alloy bridges, a more modern bridge, will have a bigger stage in the development of social modernization, and have gradually become a new consumption point for aluminum materials.

Remarks* The information comes from platforms such as Aluminum Road Network and China Nonferrous Metals News. This platform is only for sharing and not for commercial use. If there is any infringement, please contact to delete!

PREV:World Earth Day丨Cherish the Earth, Haomei will go hand in hand with you

NEXT:All-aluminum home customization is frequently being "@", or become a new trend of custom home furnishing!